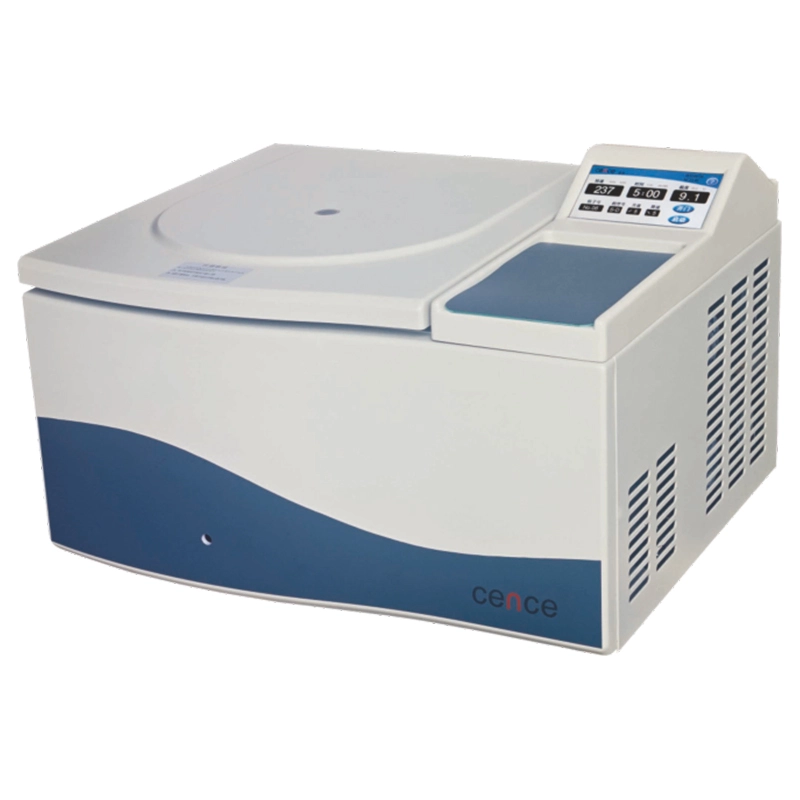

A high-speed centrifuge is a device used to separate various substances in suspension. Its main advantages include the following six.

The centrifugal efficiency of a high-speed centrifuge is so high that it can quickly separate the various components of a mixture in a short period of time. This is due to the fact that high-speed centrifuges use a centrifugal mechanism that rotates at high speeds. Under the action of centrifugal force, the various components in the suspension are separated in different directions according to different densities and weights.

High-speed centrifuges have very high requirements for separation effects and can effectively separate fine particles from liquids. It can also effectively separate the suspension with low concentration and complex mixture, and the separation effect is very good, which will not affect the product quality at all.

High-speed centrifuge not only separates well, but also runs fast and can complete the separation work in a short time. This efficient equipment can not only improve production efficiency, but also effectively reduce production costs.

High-speed centrifuge has a simple structure, easy to clean, relatively low maintenance costs, simple and quick maintenance, which can ensure its high-speed operation and separation effect.

High-speed centrifuge not only adopts the modern manufacturing process, high-quality raw materials, but also uses a good quality, systematic and complete operation control system to ensure the reliability and stability of its operation.

High-speed centrifuges have a wide range of applications, including food, pharmaceutical, chemical, environmental protection and other industries, and are widely used in operations such as separation, purification and recovery of liquids.

In summary, high-speed centrifuge has the advantages of high centrifugal efficiency, good separation effect, high productivity, simple maintenance, high reliability and wide range of applications, which is an indispensable equipment in modern chemical production.

High-speed centrifuge is an important centrifuge laboratory equipment, which separates the mixed components of the sample by high speed rotation. So what is the principle of a high-speed centrifuge?

The principle of a high-speed centrifuge comes down to centrifugal force. Centrifugal force is the centripetal force generated by the relative motion of objects as they rotate; the greater this force, the greater the separation of the centrifuged material. In a high-speed centrifuge, two rotating disks inside and outside the centrifuge are driven by a motor at speeds that can reach tens of thousands of revolutions per minute, generating a powerful centrifugal force that separates the mixed components of the sample. After separation, the different components can be collected by centrifuge tubes.

1.The use of high-speed centrifuge

High-speed centrifuge is widely used in laboratories in the life sciences, medicine, chemistry and other fields, and are commonly used for:

Cell identification and preparation, separation, enrichment of various organelles, subcellular structures and molecules, etc.

Commonly used in the preparation of DNA, RNA, proteins, enzymes, viruses and other basic biological and biochemical research

Standard testing tools and equipment for separation, purification and quantitative analysis in pharmacology.

2. Types of high-speed centrifuges

The high-speed centrifuges currently on the market are mainly divided into the following categories:

High speed benchtop centrifuge: lower speed, suitable for the separation of small samples;

Medium-sized high-speed centrifuge: faster, suitable for the separation, purification and quantitative analysis of various organelles, subcellular structures and molecules;

Large high-speed centrifuge: applicable to the separation and purification of a large number of samples, commonly used in industrial production.

3. High-speed centrifuge precautions

The use of high-speed centrifuges need to pay attention to the following matters:

Before use must be carefully familiar with the instruction manual to determine the use of normal procedures and operating procedures;

Centrifugal speed should be accelerated slowly and gradually, so as not to damage the test tube or centrifuge tube;

Routinely inspect the centrifuge once to check whether the electronic components of the brake brake and gas pedal are functioning properly, etc.. If there is a problem, it should be shut down in time and report to the maintenance personnel to repair the user do not disassemble privately;

4. High-speed centrifuge maintenance

High-speed centrifuge maintenance is also very important, after use need to pay attention to the following maintenance matters:

After use should be timely cleaning of the centrifuge tube and centrifuge;

Regular maintenance of the centrifuge motor, brake, running button twist, etc., to ensure that the centrifuge can operate normally;

Long-term non-use of high-speed centrifuge, when stored should be placed in a dry, ventilated place, and remove the brake wrench for safekeeping.

5. Advantages of high-speed centrifuge

Convenient, fast and effective advantages, widely used in science, research and development as well as production. Compared with the traditional centrifugal separation method, its features include:

High-speed rotation can produce strong centrifugal force and high degree of separation;

The ability to separate smaller components and accomplish more delicate analytical tasks;

Fast processing speed and high efficiency;

Simple and convenient operation, applicable to a wide range of fields.

In short, high-speed centrifuges can help laboratories and industries with many separations, analysis and purification of various operations, and are widely used in laboratories, becoming one of the important tools in the laboratory and production process.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt Indonesia

Indonesia

![[Science Popularization] PRP Autologous Serum Beauty [Science Popularization] PRP Autologous Serum Beauty](/uploads/image/20230814/17/science-popularization-prp-autologous-serum-beauty.webp)