(1)Before using the centrifuge

1. The placement of the centrifuge must choose a sturdy table top, with stable placement. The rubber feet of the base should be tightly pressed against the table top to prevent vibration during operation.

2. Before starting the machine, check if the rotor is firmly installed and if there are any foreign objects falling into the machine cavity. Be sure to use the centrifuge after the rotor is fixed.

3. Timely clean the accumulated water in the centrifugal chamber. When the centrifuge is running, a compressor is used for refrigeration. Due to the presence of moisture in the air, frost forms in the centrifugal chamber and water forms. At this point, the rotor should be removed, the accumulated water should be cleaned, and the door cover should be opened to allow the water vapor to dissipate.

4. The sample should be pre balanced and weighed when using centrifugation or micro centrifugation.

5. There are rubber sealing rings at the contact between the upper part of the centrifugal chamber and the door cover, as well as at the contact between the rotor seat and the bottom of the centrifugal chamber. It is necessary to regularly observe for deformation to prevent external heat from seeping in. If deformation or aging occurs, it should be replaced in a timely manner.

(2)Before using the centrifuge

1. Check the centrifuge tube sleeve. If there are foreign objects and dirt inside the tube sleeve, and if the rubber pad falls off, it should be treated immediately to maintain the balance of the centrifuge. Check the rotor for corrosion spots, grooves, small cracks, etc., and stop using the rotor and contact the production unit. Regularly maintain the rotor. When cleaning the rotor, to prevent damage to the surface oxide layer, clean it with a sponge or cotton cloth moistened with a cleaning agent. Common cleaning agents include ethanol, n-propanol, ethyl ethanol, anionic surface activator, and preservatives. After cleaning, turn it upside down and let it dry. In addition, the normal service life of rotors, suspension cups, etc. is 5 years. If the service life is exceeded, carefully inspect the rotor before use and confirm that the overall structure of the rotor is complete before use.

2. Calibrate the speed of the centrifuge, attach a reflective strip to the rotor cover, and then measure it using an infrared non-contact tachometer through the observation hole on the centrifuge cover.

3. Regularly check whether the pneumatic support rod of the door cover and the door lock switch can work properly.

4. Regularly check if the cooling fan is functioning properly; Regularly remove dust from the ventilation window and condenser of the centrifuge to ensure ventilation and heat transfer efficiency of the condenser.

5. Regularly inspect the oxidation layer on the inner and outer surfaces of the rotor. If there is peeling, corrosion, severe scratches, deformation, or cracks, they should be stopped from use. When the centrifuge is not in use for a long time, the rotor should be removed and anti rust oil should be applied to the rotor seat and drive shaft to prevent rusting.

(3)Maintenance of centrifuge

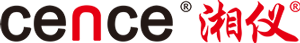

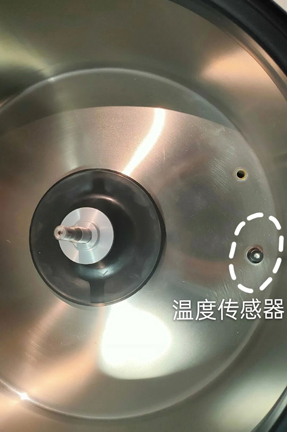

1. Maintenance of the centrifugal chamber

After the centrifuge is completed, the left ventricle should be wiped. When wiping a frozen centrifuge, attention should be paid to the position of the temperature sensor to avoid damaging it. After wiping, open the door cover for a period of time to allow the centrifuge chamber to air dry; If not used for a long time, silicone (desiccant) should be placed in the centrifuge chamber and the door cover should be closed.

2. Maintenance of the drive shaft

The installation and removal of the rotor should be light and convenient, and the rotor should be taken out vertically to prevent it from falling and damaging the drive shaft; The drive shaft should not be bumped or damaged on the cone surface. Use a soft cloth to clean the drive shaft and rotor cone holes, and apply a small amount of medical Vaseline or other lubricating grease (in the form of a paste).

3. Maintenance of control box and workbench

The control box and worktable must be kept clean, and the rotor, centrifuge tube, or centrifuge cup and other tools cannot be placed on the centrifuge panel to prevent scratches. The control box and workbench can only be wiped with a soft cloth and neutral cleaning agent to prevent the paint layer from falling off.

4. Rotor maintenance

Remove the rotor and clean it with neutral detergent. After washing, wipe it dry and invert it, allowing the water in the centrifuge tube hole to fully dry; Some users may store the rotor after high-temperature sterilization according to their own needs; Apply some lubricating oil to the center hole of the rotor and store it in a dry and ventilated place.

(4)Precautions for using centrifuge

1. When centrifuging corrosive liquids with volatile properties, brand centrifuge tubes with its own sealing ring should be used, and the liquid should not leak out to prevent corrosion of the machine cavity or accidents. Explosive or flammable substances cannot be centrifuged. For substances that are prone to react with other substances, centrifugation is also not allowed. Toxic, radioactive, or pathogenic microorganisms should not be centrifuged without corresponding protective measures, such as using containers with biological protective effects. If it is necessary to centrifuge toxic or pathogenic substances, operators must take appropriate disinfection measures and use centrifuges or rotors with biosafety devices.

Xiangyi centrifuge has specially developed a biosafety centrifuge for COVID-19, which can effectively disinfect and filter aerosols to ensure the safety of centrifuge users.

2. Do not manually open the emergency lock when the centrifuge is running, and do not open the cover to use the centrifuge at any time.

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt Indonesia

Indonesia